شرکت اشتادلر که از سال 1791 مشغول به فعالیت است و یکی از شرکت های پیشرو در زمینه طراحی، ساخت و راه اندازی سیستم های تفکیک زباله و صنایع بازیافت در جهان می باشد. اشتادلر با تجربه طراحی و اجرای بیش از 400 خط کامل تفکیک و بازیافت زباله و دارا بودن بیش از سه هزار ماشین فعال در سرتاسر جهان اکنون نامی شناخته شده در سطح بین المللی است. این شرکت تمامی سرویس های مربوط به طراحی مفهومی، طراحی مهندسی، ساخت، بهینه سازی، مونتاژ، دمونتاژ، راه اندازی و خدمات تعمیر و نگهداری را برای خطوط بازیافت و تفکیک را داراست. علاوه بر این، بخش های اصلی خطوط تفکیک با راندمان بسیار بالا توسط این شرکت و در آلمان تولید می شوند. همه پلنت های اشتادلر عملکردی بسیار بالا و پر بازده ای داشته و با به کارگیری آخرین تکنولوژی های روز دنیا می توانند مطابق با نیاز های مشتری همگام سازی شوند.

انواع سیستم های سورتینگ زباله این شرکت به شرح ذیل قابل تقسیم بندی است

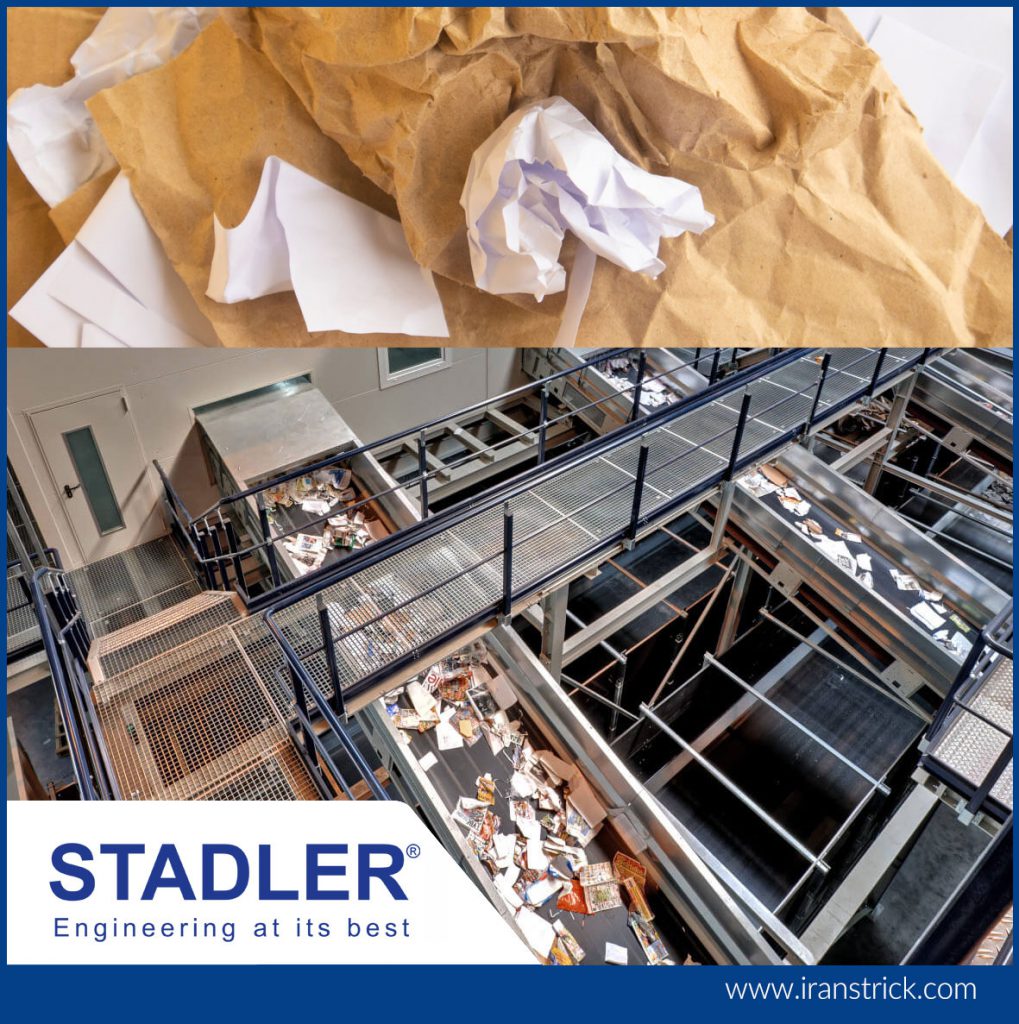

پسماند شهری انواع پسماند خانگی از جمله پسماند های آلی مانند پسماند غذایی تا مواد متـنوع قابل بازیافت دیگر را شــامل می شود. این مواد متــنوع شــامل مـوادی با چگالی 100 تا 300 کیلوگرم بر متر مکعب می شود: موردی که پلنت ها را به چالـش می کشد چرا که مدیریت این مواد نیازمند کارخانه ای منعطف اما در عین حال مقاوم می باشد. اشتادلر تاکـــنون توانسته است تا با تکیه بر توانایی های مهـــندسین خود ده ها کارخانه ســورتینگ پســـــماند شهری با ظــرفیت 40،000 تا 1 میلیون تن در سال ساخته و به مشتریان خود تحویل دهد.

امروزه جداسازی بخش آلی از مواد بازیافتی در بسیاری از کشورها انجام می شود، اما ترکیبات مواد بازیافتی خشک در هر کشور متفاوت است. این مسئله به این معناست که برای هر نوع خاصی از مواد بازیافتی می بایست کارخانه مخصوص به آن طراحی و ساخـته شود.اشتادلر در ساخت و توسعه اولین کارخانه ها از این دست دخـیل بـوده است. اشتادلر با مواد قــابل بازیافت در هر کشور آشــنا بوده و اطــلاع دارد که کــدام شرایط بهترین نتایج را برای هر مشتری ایجاد می کند.

پسماند تجاری شامل دامنه عظـــیمی از محصولات متـــفاوت است و شـــامل مـــواد و جامدات با حجم های متفاوت و چگالی به نسبت بالا می شود. این بدان معناست که فشــار زیادی بر روی ماشین آلات استفاده شده قــرار می گیـرد. اما این موضــوع بــرای دستگاه های اشـــتادلر که از اســـتاندارد های بالایی برخـــوردار می باشـــند به آســـانی قابل حل است. کارخانه های سورتینگ پسماند تجاری اشتادلر تمام جامدات و موادی که در صنایع تولید می شوند را جداسازی می کنند.

پسماند تجاری شامل دامنه عظـــیمی از محصولات متـــفاوت است و شـــامل مـــواد و جامدات با حجم های متفاوت و چگالی نسبت بالا می شود. این بدان معناست که فشــار زیادی بر روی ماشین آلات استفاده شده قــرار می گیـرد. اما این موضــوع بــرای دستگاه های اشـــتادلر که از اســـتاندارد های بالایی برخـــوردار می باشـــند به آســـانی قابل حل است. کارخانه های سورتینگ پسماند تجاری اشتادلر تمام جامدات و موادی که در صنایع تولید می شوند را جداسازی می کنند.

یکی از زمینه های تخصصی اشـتادلر پیش-جدا سازی (Pre-Sorting ) بطـری ها برای پلنت های شستشو است. تجربه عمیق اشتادلر باعث می شود که بالاترین خلوص در خروجی پایانی به دست آید به طوری که برای فرایندهای بعدی همه موارد آماده باشد. پلاستیک های ترکیــبی پرس شــده و ترکیــبات پــرس نشــده بطـــری های پلاسـتیکی، در چارچوب سورتینگ بطری های پلاستیکی پردازش می شوند.

کارخانه های ســـوخت مشتق شده زباله اشـــتادلر به طور حـــرفه ای ضایعات تجاری و همچنین زباله های از پیش طبقه بندی شده حاوی پلاسـتیک را پردازش می کنند، که در خدمت تولید سوخت های مشتق شده زباله با کیفیت بالا برای تولید سیمان است. سوخت های مشتق شده برای تولید سیمان باید کیفیت بالا و با ثبــاتی داشته باشند. بنابراین کارخانه های اشتـــادلر ترجیحا از فــرآینــدهای جــداســازی مکانیکی اســتفاده می کنند. از اولـــین کارخانه در ســـال 2005 تا به امــروز، اشـــتادلر تـــعداد ده کارخــــانه ســـوخت مشـــتق از زباله را راه انـــدازی کـــرده است که همـــگی بیـــش از انتـــظـــاراتراضی کننده هستند.

ترکیب مواد در زمینه پسماند های الکتریکی و الکترونیکی شامد انواع مختلفی از وســـایل الکترونیکی در انـدازه های مختــلف می شوند. موبـایل، کامپیوتر، پرینتــر، تلویـــزیون، مخـــلوط کن، یخـــچال و سیستم های تهویه هـــوا از جمله این وسایل می باشند. پلنــــت های سورتیــــنگ برای پسماند های الکتــــریکی و الکترونیـــکی می بایست برای بازار پر متـقـاضی، بالاترین کیفیت و رضایت را داشته باشد.

بنابراین نیاز است که چنین پلنت هایی بتوانند علاوه بر جداسازی انواع مختلف فلز، آنها را از صفحــات پلاستــیکی و روکش ها نیز جــدا کرده و آنها را به جریان خـوراک بازیافتی هـــدایت کنند.اشــتادلر با همکاری شــرکت WeeeSwiss Technology با بیش از 25 ســال ســابقه در بازیافـت پسمــاند های الکتریکی و الکتــرونیکی، پلنــت های سورتینگ بی نظیری از لحاظ کیفیت و بازده تولید می کند.

ترکیب مواد ساختمانی یا پسماند های حجیم شامل مواد مقوایی، چوبی، فلزات آهنی، معـــدنی و نایــلون ها می شوند. ترکیب مـــواد حجـــیم با چگالی بالا نیازمند ســـاخـت پلنت هایی با تجهیزات مقاوم و کارایی بالا می باشد. به منظور برآورده کردن این نیـاز، اشتادلر جداکننده بالیستیک بسیار قدرتمــند STT6000 را طراحی نموده که مختص این نوع پلنت ها می باشد.

مواد ورودی این نوع پلنت ها شامل تمام انـواع چوب، که دارای عناصر آهنی مانند میخ، پیچ، شیشه یا ناخالصی های دیگر هستند را شامل می شود.

اشتادلر توانسته است پلنت های سورتینگ چوب با بــازده بالا را طراحی و تولید کند که توانایی بازیافت حداکثر میزان چوب را داشته باشند. اولین پلنت از این دست در سال 2012 نصـب و راه اندازی شده است. هدف اصلی این نــوع پلـنــت ها جـداسازی تمامی موادی است که فرایند را دچار مشکل می کنند.

انواع محصولات و خدمات این شرکت به شرح ذیل قابل تقسیم بندی است

تفکیک کننده های بالستیــک جهت جداسازی مواد حجــیم و 3 بعدی از مواد 2 بعـدی مورد اســـتــفاده قـــرار می گیــرند. تاکنــون بیـــش از 750 دســـتگاه از این نــوع توســـط شرکت اشتادلر تولید ودر سراسر دنیا نصب و راه اندازی شده است.

خصوصیات برجسته تفکیک کننده های بالستیک:

- جداسازی مواد غلطنده و سنگین مانند بطری ها، سنگ، چوب، قوطی ها و قطعات فلزی

- جداسازی مواد تخت و سبک مانند فیلم ها، منسوجات، کاغذ، مقوا و الیاف

- قابلیت جمع آوری مواد زیرسرندی

- مجهز به سیستم NIR

- جداسازی زودهنگام شیشه

- رانـــدمان انـــرژی بـــالا

درام های اســـتوانه ای ساخـــت این شـــرکت برای تفــکیک موثــر مواد به سایز های مختلف و به صورت همگن، با راندمان بسیار بالا کاربرد دارند. این فــــرآیند به کمــک تنظیم سرعت، تنظـــیم شیب و تعــویض پوسته های داخلی، قابلـــیت بهینه شدن را داراست.

بـــرخی از ویـــژگی های درام های استوانه ای:

- سازه مستحکم

- سیستم های بیرینگ دو طرفه

- قطعات با طول عمر بالا

- تعمیرات و نگهداری آسان

- سیستم های محافظ گرد و غبار

- سیستم کنترل سرعت

- تغذیه و تخلیه بهینه

- سیستم کنترل لرزش (کمترین لرزش در بالاترین سرعت)

نوار نقاله های ساخت شرکت Stadler به لطف طراحی مدولار در انواع مختلف و برای کاربردها و شرایط کاری مختلف مناسب می باشند. ایـــن سیســتم مدولار با نصب ســـریع و آسان در سایت تولیـدی، هزینـه ها و دقـــت تقسیم بندی و جابجایی مواد را به شدت افزایش میدهد.

سیستم انتقال مواد اشتادلر در انـواع مختلف جهت مـــواد مختلف از لحـــاظ ابعاد و وزن عرضه می شود و به لطف کنترل دقــیق سرعت در تمام خط قابلیت جدا سازی و هدایت مواد با سنسورهای پیشرفته و با ضریب خطای صفر را فراهم می نماید .