شرکت ایتالیایی FORTEC بیش از 40 سال سابقه در طراحی، تولید، فروش و نصب پلنت های اکولوژیک پیشرفته برای مدیریت پسماندهای بیمارستانی، شهری و صنعتی دارد. از جمله برتری های این شرکت توانایی تولید دستگاه های زباله سوز برای هر نوع پسماند و پلنت های زباله سوز منطبق با نیاز های مشتریان می باشد. محصولات این شرکت بسیار با کیفیت و مطمئن بوده و بازدهی بالایی دارند. دستگاه های تولیدی این شرکت دارای تاییدیه کامل CE بوده و مطابق با آخرین قوانین وضع شده سلامت، محیط زیست و ساختمانی می باشند.

ویرایش محتوا

این دستگاه های دارای اتاقک های احتراق استاتیک یا ثابت (برخلاف Excotec که مدل قابل حمل بود) یا چندمرحله ای برای از بین بردن پسماند های با مقدار گرمازایی پایین.

اطلاعات فنی:

ویژگیهای برجسته EXCOTEC :

- دمای کار بین 850 تا 1100 سانتی گراد است.

- ظرفیت سوزاندن بین 40 تا 600 کیلوگرم پسماند در ساعت است.

- حذف مواد آلی فرار(VOCs) توسط اتاقک پسا احتراق.

ویژگیهای برجسته EXCOTEC :

- سیکل کاملا کنترل شده و اتوماتیک

- کمترین میزان انتشار گاز

- سیستم بازیافت انرژی از اتاقک احتراق،با بهینه سازی مصرف سوخت، نسبت به آون های معمول باعث صرفه جویی عملیاتی بالایی می شود. همچنین می توان آن را با هزینه بسیار کم با سیستم های بازیافت انرژی دیگری برای مصارفی از جمله آب گرمکن و ایجاد بخار ترکیب کرد.

- این اتاقک احتراق نیز دارای اتاق احتراق ثانویه برای حذف آلودگی هاست. سیستم حذف آلودگی خشک(Dry depuration system) را می توان با این سیستم ترکیب کرد.

ویرایش محتوا

جهت حذف پسماندهای بیمارستانی و صنعتی به خصوص پسماندهایی که مقدار گرمازایی آنها پایین است (L.C.V.)

اطلاعات فنی:

ویژگیهای برجسته EXCE OS:

- عایق بندی توسط کلسیم سیلیکات و بتن دارای آلمینیوم اکسید که می تواند دماهایی بالاتر از 1600 درجه را تحمل کند

- درب جنس فیبر سرامیکی HT-Z و گیره های استنلس استیل

- حجم آون ها از 0.4m3 تا 10m3 می باشد

- ظرفیت سوزاندن برای کمترین حجم: 30 کیلوگرم در ساعت

ویژگیهای برجسته EXCE OS:

- کارایی چندگانه جهت سوزاندن هر نوع پسماند.

- افزودن آسان پسماند به علت حالت ویژه طراحی درب که در قسمت بالایی تعبیه شده(قابلیت اتوماسیون سیستم بارگزاری و برداشت پسماند)

- آون ها جهت حمل آسان قابلیت نصب بر روی تریلی را دارند.

- زباله ها در دماهای بالای 1000 درجه سوزانده می شوند تا تمامی آلودگی ها از بین رفته و خروجی فرایند خاکستر خالص است.

- گاز های حاصله از سوخت اولیه زباله ها وارد اتاقک احتراق ثانویه می شوند و در دمای بالای 1100 درجه سوزانده می شوند تا کاملا اکسیده شده و دیوکسین ها(ِDIOXINs) تشکیل نشوند.

- حرارت در زباله سوزها به صورت کاملا یکنواخت توزیع شده و منطبق با استاندارد های DIRECTIVE 2000/76/EC می باشد.

- این زباله سوز ها دارای استاندارد های ISO9001:2015 و ISO14001:2015 می باشند.

ویرایش محتوا

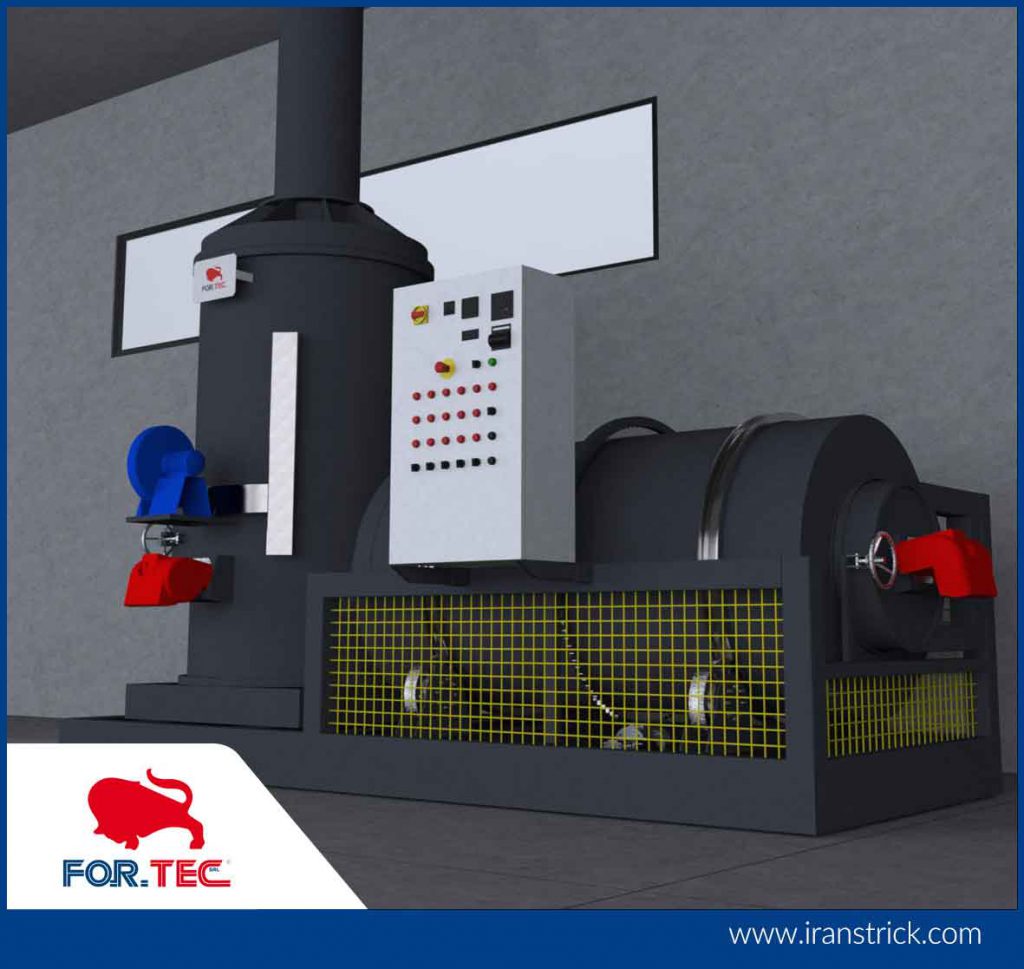

این دستگاه دارای اتاقک احتراق چرخشی است و به طوری عمل می کند که تمامی پسماندها به طور کامل و بدون باقیمانده سوزانده شود و بیشینه حرارت به تمام قسمت های پسماندها برسد. این دستگاه مناسب مدیریت و تخلیه پسماندهای خشک و تر می باشد.

اطلاعات فنی:

ویژگیهای برجسته ROTOMAC:

- دمای عملیاتی بین 850 تا 1000 درجه سانتی گراد.

- حجم آون ها از 0.9m3 تا 6m3 می باشد.

- ظرفیت سوزاندن برای کمترین حجم: 100 کیلوگرم در ساعت.

ویژگیهای برجسته ROTOMAC:

- آرگانومی این دستگاه به نحویست که می تواند فرایند آبگیری از پسماند را شتاب دهد که نسبت به زباله سوز های نوع ثابت باعث کاهش مصرف سوخت می شود.

- هر زباله سوز روتاری دارای اتاقک پسا احتراق می باشد که مطابق با اخرین استاندارد های اروپا آلودگی های ناشی از سوزاندن پسماند را کنترل می کند.